Overview

The side-entry mixer is a kind of mixing device that installs the mixer on the side wall of the cylinder, most of which are mainly used for liquid-liquid phase material mixing, solid-liquid phase material suspension and dissolution, etc., which can strengthen the mass transfer and heat transfer between phases; In the case of the same power consumption, the power consumption is only 1/3-2/3 of the top-entry mixer, and the cost is only 1/4-1/3 of the top-entry mixer;

Uses and characteristics

Side-entry mixers are widely used in environmental protection, water treatment, biogas fermentation, flue gas desulfurization engineering, petrochemical, papermaking, construction, food and other large storage tanks;

1. The equipment runs smoothly, safely and reliably;

2. Energy saving and environmental protection, low energy consumption, high transmission and mixing efficiency;

3. Compact and reasonable structure, easy to operate, small footprint;

4. Low investment and operation and maintenance costs;

Main structure

There are a variety of structural forms of side-entry mixers in the market, and there are two main structural forms produced by Sealok, one is a double-fulcrum frame side-entry mixer, and the other is a side-entry mixer with an internal support frame, and the two mixers are selected and used according to the different process application environments and needs of customers; The transmission parts have different transmission methods such as V-belts, synchronous belts, gears, and magnetic drives; Sealing is very important in the mixing of large storage tanks, and our company adopts various forms such as mechanical seals, packing seals, labyrinth seals, and combined seals according to the needs of customers in different use environments; Generally, the side-entry mixer of large storage tanks is equipped with a sealing crisis treatment mechanism, and customers can easily replace the sealing ring without emptying the filling material during failure or maintenance.

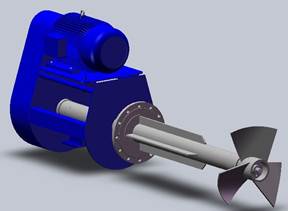

1. Double fulcrum rack side-entry mixer

The structure is relatively simple, mainly composed of motors, pulleys, double fulcrum frames, stirring shafts, mounting flanges, mechanical seals, packing seals, impellers and other components. The adaptive speed is generally less than 350rmp; Choose different mechanical seals according to different materials.

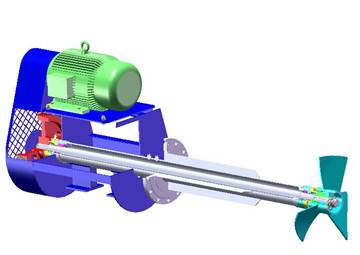

2. Main mechanism of the side-entry mixer with inner support frame:

The whole is mainly composed of motor, pulley, motor bracket, inner support frame, mounting flange, stirring shaft, mechanical seal, auxiliary sealing mechanism, impeller, bearing and other components. There is a set of sealing system at both ends of the inner support frame, and two sets of mechanical seals are generally used to be safe and reliable, if the use environment requirements are not high, only the structural form of a set of mechanical seals at the outer end will be used in order to save costs, or the combined sealing form; The auxiliary sealing mechanism, mainly designed for fault emergency and convenient maintenance, does not need to empty the material in the tank, only need to pull the shaft out of the tank for a distance, the auxiliary seal on the shaft will enter the sealing seat, and the seal is locked after rotating a certain angle, so as to prevent the material from leaking, and rest assured to replace the sealing ring.

Inner Support Frame Side-entry Mixer Features:1. The short-range double fulcrum structure of the agitator has better rigidity, more stable and reliable operation, longer depth of mixing paddle, and strong process adaptability; For example, it can adapt to the solid-liquid suspension stirring with higher solid content in the tank, and adapt to the stirring of higher viscosity fluids; 2. Wide range of speed adaptation: 0-600rmp; 3. Adopt the unique double mechanical seal and auxiliary seal structure design, the safety of the storage tank is higher, and the maintenance is more convenient;

Inner Support Frame Side-entry Mixer Features:1. The short-range double fulcrum structure of the agitator has better rigidity, more stable and reliable operation, longer depth of mixing paddle, and strong process adaptability; For example, it can adapt to the solid-liquid suspension stirring with higher solid content in the tank, and adapt to the stirring of higher viscosity fluids; 2. Wide range of speed adaptation: 0-600rmp; 3. Adopt the unique double mechanical seal and auxiliary seal structure design, the safety of the storage tank is higher, and the maintenance is more convenient;

Technical parameters of the side-entry mixer

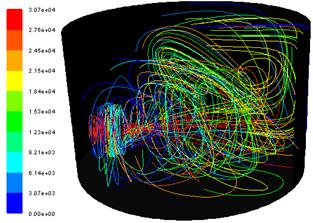

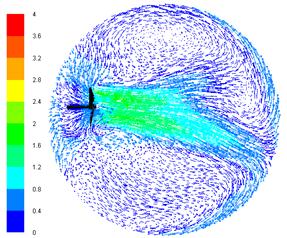

1. Advanced impeller design

Using advanced computational fluid dynamics (CFD) software, we can accurately simulate the flow field, mixer installation position, impeller structure optimization and other important parameters to ensure the performance of our mixing equipment to achieve the ideal state.

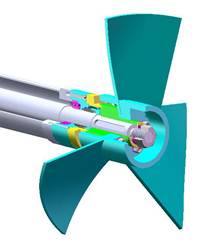

2. Optimized design of propellers

The impellers are optimally designed using computational fluid dynamics (CFD) methods to ensure optimal mixing efficiency every time they are designed.

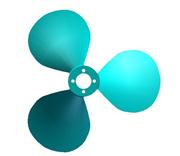

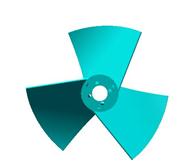

The different propeller types are as follows:

1. Type A propeller propeller and type B high-efficiency curve axial flow agitator are suitable for processing fluids with small tanks and low viscosity (less than 2500cp), and need to mix the fluid in a short time. For example, the operation of evenly distributing additives in the fluid in the tank;

2. C-type wide-blade axial flow propeller is suitable for mixing and high solid content of higher viscosity (2500~10000cp) fluids. For example, in biogas fermentation, where the solid content is high and the fluid viscosity is high, the mixing equipment using C-type paddles can handle the fermentation broth with a slurry viscosity of 5000cp (solid content of 10 or more).

Engineering applications

Biogas fermentation: stir the fermentation raw materials and biogas microorganisms to fully mix, and the uniform contact makes the microorganisms have sufficient food, ensure normal fermentation, and improve the gas production rate. Prevent raw materials from being divided and cleaned and precipitated.

Flue gas desulfurization: In desulfurization, it is mainly used in large containers such as slurry tanks and absorption towers to stir the slurry in the tower to prevent the suspension from precipitating, and at the same time, the oxidation gas and the paddle are fully mixed with the bulging in.

Others: large crude oil storage tanks, pulp and paper, lubricating oil storage tanks, edible oil storage tanks, etc.